Adhesive Peel Tester company|adhesive peel testing : wholesale Peel testing allows accurate measurement of the performance of seals, coatings and adhesives and gives invaluable information to resolve failure investigations for adhesives failure and . webOrdem de Sorteio Ordem de Acertos. Simulador de números da MegaSena para conferência dos resultados de todos os concursos, concursos anteriores, ferramenta para montar e testar jogos.

{plog:ftitle_list}

Resultado da 16 de jun. de 2023 · 1. Welche Stars sind in "Outlander" Staffel 7 dabei? 2. Wann startet die 7. Staffel von "Outlander"? 3. Wann gibt es "Outlander" Staffel 7 in Deutschland zu sehen? 4. Wann kommt die 7. Staffel von "Outlander" zu Netflix? 5. Um was geht es in der 7. Staffel von .

Peel testing allows accurate measurement of the performance of seals, coatings and adhesives and gives invaluable information to resolve failure investigations for adhesives failure and .

Scratch testing carried out by our experts is invaluable to gain insight into materials .Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive .There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main . ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to.

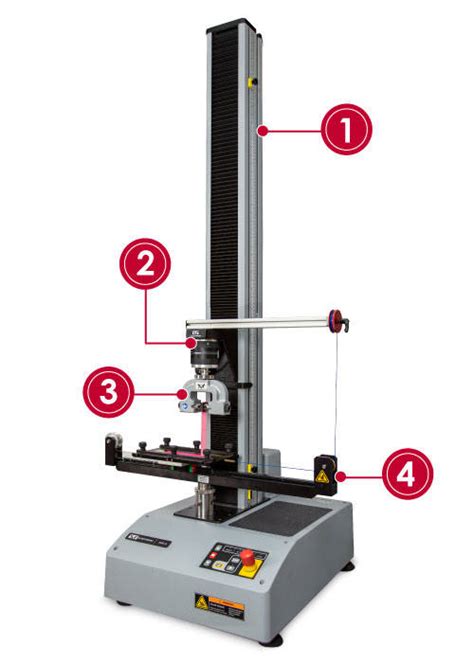

This article goes into what adhesive testing methods you might need. . Cataplasma testing – This is similar to the ‘cut and peel’ test process, but still not exactly the same. This test will put the adhesive through a similar climate in .Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330

ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials. ISO 11343 is a standardized Wedge Peel Impact test method used to measure the resistance of high-strength structural adhesives to cleavage fracture at various speeds and user-defined temperatures. The impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into the adhesive bond securing two metallic .

The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

PSTC-101 is a standard test method to measure peel adhesion strength in pressure s. FTM-9 Pressure Sensitive Tape Loop Tack Test Equipment. Loop tack tests provide the means of assessing the most important and yet the hard. ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds . Company / OrganizationPeel testing is a form of materials testing designed to test the mechanical properties of adhesives. . Our Company. Careers Subscribe to Our Newsletters. About Us. Our History. Locations. . Peel Adhesion 90° ASTM D1876 Peel Resistance for Adhesives, T-Peel Test EN 12242 Peel Strength Touch and Close Fasteners (Hook and Loop) .Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

ASTM peel adhesion testing is a tool for quality assurance use. At ATS, it is our policy to provide our clients with the highest quality testing services. Our ISO 17025 accredited lab performs ASTM peel adhesion testing to the most stringent applicable standards and specifications. Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.ASTM D903 is a standard test procedure developed in accordance with international standards to determine the comparative peel or stripping characteristics of adhesive bonds. ASTM D903 provides guidance on testing standard-sized specimens at precisely controlled test machine speed. Our engineers are familiar with the ASTM D903 test procedure and can guide you . A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .

Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw .This type of testing is often used in the manufacturing and construction industries to determine the strength of adhesives. There are a variety of adhesion testers on the market, but all operate by applying a known force to a sample and measuring the displacement. Some testers also measure the time it takes for the adhesive to fail. A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .Typically the goal of a peel test is to determine the adhesive strength of the material or the strength of the adhesive bond between two materials. This adhesive strength may be referred to as the “stickiness” of the material as it is a measure of the resistance of specimens to separate from each other after the adhesive is applied.

To conduct a peel test, a specimen is prepared by bonding two materials together using an adhesive. The sample is then mounted in a peel testing machine, which pulls one material away from the other at a specific speed and angle, usually 90° or 180°.The force required to separate the materials is continuously measured during the test.Product Description: Qualtech Products Industry Peel Tester is an Automatic Peel Tester for flexible bonded to rigid test specimen to measure the Adhesive Strength of a wide range of samples at the touch of a button including adhesives. This professional Automatic Peel Tester offers the newest microchip technology combined with a large Color Touchscreen Display, .

Pressure Sensitive Tape Council PSTC Test Methods (PSTC-1 to PSTC-136) peel adhesion on tapes. Peel Testing Standards by Standards Organization: . We use the 100 Family Electromechanical Universal Test Machine made by TestResources often at our company. As a provider of adhesion promoters and other specialty products, peel testing plays an . 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.Elcometer offers a wide range of adhesion testers used to verify that both surface preparation and coating application are within specification. Elcometer adhesion testing gauges use destructive methods, including pull off adhesion test, push off adhesion test and cross hatch/ cross cut test, to measure how well the coating adheres to the .The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .

Elcometer 106 Pull-Off Adhesion Tester; Designed to measure coatings adhesion on concrete. Elcometer 106/6 Coatings on Concrete Adhesion Tester; A versatile push off gauge used to test adhesion on flat or curved surfaces. Elcometer 108 Hydraulic Adhesion Testers; Used for an instant adhesion assessment, ideal for thin, thick or tough coatings .

peel testing system

(a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is .Peel testing typically involves several variables which must be managed in order to ensure consistent and repeatable tests. Those variables include angle of the peel, rate of the pull, pressure with which the adherands are pushed together, and the surface characteristics of the adherands. ASTM D6252 is a common test method to measure the peel adhesion of .

vickers hardness test hv1

22 de nov. de 2023 · A new poker room featuring 33 card tables, a full bar, intertrack .

Adhesive Peel Tester company|adhesive peel testing